WRB, Openings, RAIN SCREEN & More

When building a custom home, it’s important to have confidence in the weatherproofing materials, but especially on the coast, and especially for a homeowner who requests additional preventative measures to protect the home and its residents from moisture, leaks, and mold.

We selected Henry Blueskin because it provides a proven comprehensive watertight moisture and water protection system. Henry products also make the home more energy efficient by preventing air leaks. To create a high-performance building envelope we plan to install the Henry® 1-2-3 Moisture Control System™ which is backed by a 15-year warranty:

- Blueskin® VP100: a fully bonded, self-adhered sheet that is easy to apply, vapor permeable, and nail sealable for an additional level of protection. This provides reliable high performance and durability over the long term and will “prevent moisture and air leakage”.

- Blueskin® Butyl Flash: self-seals around nails and fastener, free from asphalt.

- Air-Bloc® LF Liquid-Applied Flashing: for high-performance protection from leaks, as it smoothed out slight irregularities in rough openings to achieve a perfect, water-tight fit around headers, jambs, and sills.

- Moistop® Sealant made for integral door pans.

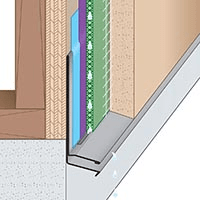

- Henry’s WeatherSmart® Rainscreen: a 3D matrix polypropylene that channels water out of the wall assembly and provides a 6mm ventilation gap between the exterior stucco application and the VP100. The gap will also allows the wall cavity to dry faster. In 2025 this will become mandated for all stucco builds. Currently, asphalt soaked paper is used here which can get moldy.

- 212 All Purpose Crystal Clear Sealant for reverse laps and pipe penetrations

- Blueskin® Spray Prep – Aerosol to seal Blueskin to the concrete slab and prevent air flow through the mud sill.

What’s just as important as the product is the installation of the product, inspections over time, and repairs. We were fortunate to have the help from our local California rep on speed dial to help answer questions and inspect the work periodically. This was critical for our project as the 1/4″ rain screen made all of the flashing much more expensive and complicated.

In order to install the rain screen we needed weep screeds that accommodate the 7/8″ stucco and 1/4″ Rain screen (in lieu of the typically used black asphalt paper that may get wet and mold over time). We selected aluminum metal to match our window and door frames by Stockton Products: Tru-Weep™ Stucco Stop. It was a custom order and took several weeks to be custom made. We then needed custom j-beads around the windows and doors as we did not have the foresight to have them manufactured with the extra 1/4″. And then stucco stops for the top roof line and overhangs.